Consumer Electronics

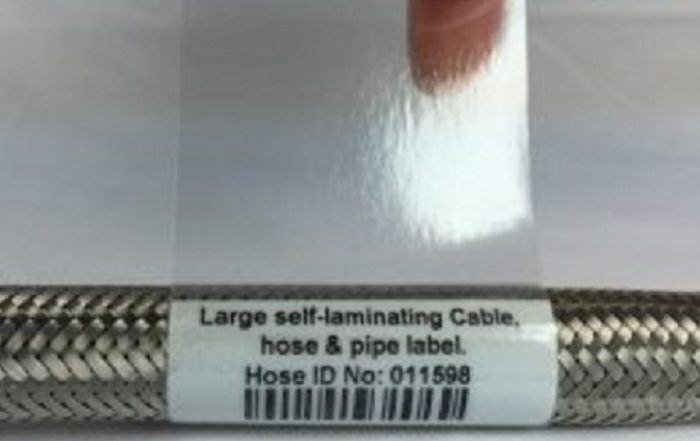

PCB Circuit board product traceability identification – label.

Ruilisibo provides high temperature identification labels for PCB manufacturing and component ID. The labels can withstand the ultra-tough, industrial applications of PCB process. Our materials stand up to solvents, wave soldering and hot-air leveling.

PCB Label

PCBA labels are printable with barcodes to accurately track products through all phases of manufacturing, saying reflow oven, wave soldering reflow and chemical cleaning cycle.

ESD Label

Electrostatic dissipative (ESD) label withstands wave solder environments and multiple harsh washes for printed circuit board and electronic component preprocess.

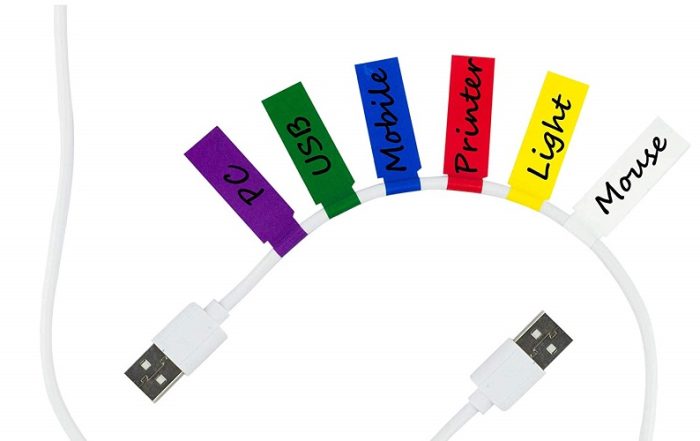

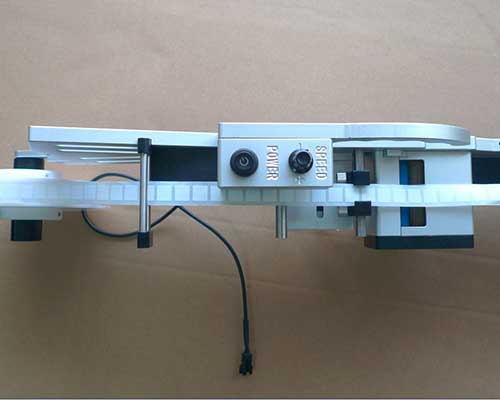

Auto-Apply Label

Designed to be used with the Label feeder for automatic labeling, these labels are ideal for your printed circuit board and electronic component preprocess labeling applications.

Features:

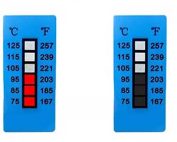

Resistant to extremely temperature up to 350°C

Superior chemical and abrasion resistance

Withstand high heat reflow, non-reflow and wash processes

Be able to do smallest size to 2mm x 2mm

Advantages and benefits:

PCB labels are thermal transfer printable with barcodes or variable date to accurately track their products through all phases of manufacturing, saying soldering reflux ( reflow oven ), wave soldering reflow and chemical cleaning cycle.

Polyimide PCB labels remain stable at high temperatures. The coatings facestock are able to resist the harshest of fluxes without smear after processes including wave solder, reflow, high pressure washes, and most cleaning processes .